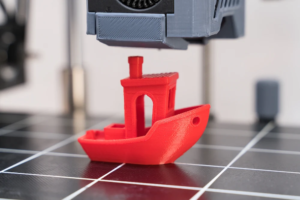

3D Printing Phoenix AZ is a process that turns a digital model into a physical three-dimensional object by adding layers of material. This has the potential to transform manufacturing, logistics, and inventory management.

There are several different printing processes that vary in speed, cost, and versatility with respect to feedstock material. This article will explore some of the major methods, including VAT photopolymerization, powder bed fusion, and direct energy deposition.

Prototyping with 3D printing enables designers to create prototypes to test or validate design ideas and concepts. It also provides an opportunity to discover design errors, reducing the chances that those errors will be introduced to the final product.

The process begins with a digital model created using computer-aided design (CAD) software. This model is then sent to a 3D printer, which builds the prototype layer by layer until it has reached its desired size and shape.

Visual prototypes are primarily used to test out appearance factors like color, texture, and shape. They are an excellent way to validate a design while minimizing the time spent on an iterative design process. They are often used early in the development of a new product, for example, to ensure that a potential industrial design or aesthetic line is compatible with a newly developed form factor.

Functional prototypes, on the other hand, are meant to demonstrate and verify a product’s functionality. They are usually constructed of materials similar to those that will be used in the final product, ensuring that they function properly, including whether load-bearing parts can handle the weight and stress of the product. This type of prototyping is ideal for 3D printing because it allows engineers to conduct thorough performance evaluations of the prototypes and make necessary changes.

During this stage of development, it is important to test the prototypes in realistic conditions and to gather feedback from users. This can help identify any problems or incompatibilities with other components, such as electrical or mechanical systems. This can save valuable engineering resources that would be required to go through a full manufacturing process if the error was discovered at an earlier stage in the development cycle.

Engineering or pre-production prototypes are the last category of prototypes and are commonly used to demonstrate a final product to investors, customers, resellers, and manufacturers. They are an effective tool for demonstrating the value of a new product and can be useful in securing funding or sales opportunities. 3D printing is an excellent choice for creating these prototypes because it can be cost-effective when compared to traditional forms of manufacturing. For example, noise-level monitoring company NoiseAware was able to reduce the cost of their prototypes from $800 per product to just $15.

Rapid Manufacturing

3D printing is a type of additive manufacturing process, which builds up an object sequentially rather than casting or milling them from a solid block (subtractive processes). As such, it produces far less waste than traditional fabrication methods. In addition to being environmentally friendly, this method is also extremely cost-efficient. In fact, some companies can even produce their products in-house, saving them time and money that would otherwise be spent on outsourcing production to third-party manufacturers.

With rapid prototyping, it’s possible to test and develop products at a fraction of the usual industrial wait times. The speed of production can give businesses a competitive advantage in a fast-changing market and reduce the amount of capital that is required to bring products to market.

The first step in the prototyping process is to create a virtual model of the product using computer-aided design (CAD) software. This software allows engineers to create precise drawings and technical illustrations of the product and how it will be assembled. Once the design is complete, it can be prepared for 3D printing by slicing it into many layers. The layering technique allows the printer to deposit material at a precise rate, enabling the creation of complex shapes and intricate details.

Depending on the complexity of the product, prototypes can be made from polymers, metals or ceramics. Most commonly, polymers are used because they are strong, durable and can be printed at a high resolution. Polymers can be printed in a variety of colors, and can be infused with other materials to provide extra strength or electrical conductivity. For example, adding a flexible plastic like nylon can make the final product more flexible and easier to handle.

When it comes to advancing the production of a new product, engineers use high-fidelity prototypes to validate the design’s fit, finish and function before moving forward with tooling for mass production. With the help of 3D printing, engineers can quickly iterate designs, reducing the risk of costly errors and improving the product’s overall quality.

The most advanced 3D printers can be used to create functional prototypes that are ready for testing in real conditions. These are often used to replace traditional prototypes in a wide range of industries, including aerospace, automotive, medical and consumer goods.

Customization

3D printing makes it possible to customize products to the specific needs and preferences of each customer. This can be done using computer-aided design (CAD) software to create digital models that are modified for each customer, or it can be achieved by combining multiple designs into one final printed product. The ability to customize products in this way is transforming manufacturing and creating new possibilities for business innovation.

A number of factors are contributing to the growth of customization with 3D printing, including advances in CAD software and materials. 3D printers are becoming more versatile and cost-effective, allowing manufacturers to produce larger and more complex products. Additionally, 3D printing does not require the creation of specialized molds, which can be expensive and time-consuming. This allows businesses to iterate and modify designs more quickly, which is essential for achieving mass customization.

Customization with 3D printing can be used to create a wide variety of consumer goods, from medical devices that are tailored to an individual’s specific anatomy to fashion accessories that reflect their personal style. The ability to make customized consumer goods is a major opportunity for companies looking to differentiate themselves from competitors.

However, it is important to note that 3D printing is not without its limitations. Some geometries and intricate details may be difficult to produce, depending on the capabilities of the 3D printer and the material being used. In addition, the production of a finished 3D-printed product often requires post-processing, such as sanding or smoothing to achieve a desired finish, heat treatment to achieve specific material properties, and/or machining to remove supports or other internal structures.

Despite these limitations, customization with 3D printing has become a common practice in a wide range of industries. For example, the luxury Italian furniture company Poltrona Frau offers customers the opportunity to design and print their own unique pieces on its website. In a world where fashion is often criticized for its rapid turnover and overconsumption, this type of customization is an excellent way to encourage consumer creativity and allow individuals to assert their personal style.

Sustainability

Many manufacturers are evaluating 3D printing as an alternative to traditional manufacturing processes that generate high levels of waste and environmental impact. With 3D printing, known as additive manufacturing, a wide range of products can be made on-demand and from materials that are both durable and eco-friendly. This technology could help reduce the need for large manufacturing facilities that create noxious fumes, as well as cut back on the amount of energy used for production.

Conventional substrative manufacturing uses cutting, drilling and shaping tools to create a desired product. This process produces significant amounts of production scrap, with up to 90% of the raw material discarded. With 3D printing, a product is built layer by layer using only the material required to make the final part. This can slash waste by up to 90% compared with traditional methods, according to Forrester Research.

3D printers use a variety of different materials, including plastics, metals and alloys, and some are able to work with recycled polymer feedstocks. Choosing a bioplastic like PLA or PETG made from renewable resources can help decrease energy consumption, as can printing with materials such as nylon, which is recyclable and has an excellent strength-to-weight ratio. In addition, printing with recycled and recyclable polymers reduces the extraction of natural resources, transportation costs, emissions from raw material sourcing and processing and the disposal of waste.

The versatility of 3D printing has created a number of unique sustainability projects that are changing the way we think about what’s possible. One example is Reef Arabia, an artificial reef company that prints marine-grade sandstone coral to be planted in the ocean, helping regenerate depleted marine ecosystems. Other companies are recycling 3D printed parts by incorporating them into new, greener products such as bicycle frames and car dashboards.

Considering the environmental benefits of 3D printing, it’s no surprise that its use is growing across multiple sectors. Whether it’s in aerospace, automotive or healthcare, this innovative technology is changing the way we build and create things. With the potential for increased efficiency, cost-effectiveness and sustainability, it’s clear that the future of manufacturing looks very bright indeed.